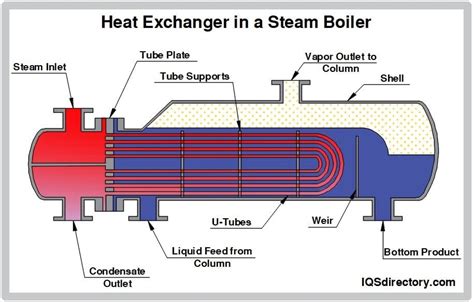

Steam boilers are indispensable industrial equipment, playing a crucial role in generating process steam for various applications across industries. Comprising a closed vessel, it functions by heating water until it transforms into steam, providing a reliable and efficient source of heat.

What is a Steam Boiler?

A steam boiler is a closed vessel designed to generate steam by heating water under controlled conditions. It is a key component in industrial processes, providing a consistent and dependable supply of steam for various applications. Boilers are engineered to operate at specific pressures and temperatures, ensuring optimal steam quality and efficiency.

How Does a Steam Boiler Work?

The operation of a steam boiler can be summarized as follows:

- Water Intake: Feedwater enters the boiler through a feedwater inlet.

- Heating: The water is heated by a heat source, typically fossil fuels like natural gas or coal, or renewable sources like biomass.

- Steam Generation: As the water temperature rises, it reaches its boiling point and begins to vaporize, forming steam.

- Steam Release: The generated steam is collected in a steam drum or steam separator and released for use in various industrial processes.

Types of Steam Boilers

Steam boilers are classified into various types based on their design, fuel source, and operating characteristics:

- Water-Tube Boilers: Water flows through tubes heated by hot gases, generating steam.

- Fire-Tube Boilers: Hot gases pass through tubes surrounded by water, heating the water and producing steam.

- Packaged Boilers: Compact, pre-assembled units, typically used for low-capacity steam needs.

- Electric Boilers: Utilize electricity as the heat source to generate steam.

Applications of Steam Boilers

Steam boilers find widespread applications in diverse industries, serving as a vital source of heat and power:

- Process Steam: Used for heating, drying, sterilization, and other manufacturing processes in industries such as food, textiles, and pharmaceuticals.

- Power Generation: Steam drives turbines to generate electricity in power plants.

- District Heating: Steam is distributed through underground pipes to provide heat for buildings and homes.

- Industrial Cleaning: Steam is employed for cleaning and sanitizing equipment and surfaces in industries like food processing and manufacturing.

Benefits of Using Steam Boilers

Steam boilers offer several advantages in industrial operations:

- High Efficiency: Modern boilers achieve high combustion efficiency, optimizing fuel consumption and reducing operating costs.

- Reliability: Steam boilers are designed to provide reliable and continuous steam output, ensuring uninterrupted operations.

- Controllability: Boilers can be precisely controlled to maintain specific steam pressure and temperature, meeting varying process requirements.

- Versatility: Steam can be used for multiple applications, including heating, power generation, and cleaning, offering flexibility in industrial processes.

Safety Considerations for Steam Boilers

Safe operation of steam boilers is paramount to prevent accidents and injuries:

- Regular Inspections: Boilers should undergo regular inspections and maintenance to ensure their safe and efficient operation.

- Proper Training: Operators must be adequately trained and certified to operate steam boilers safely.

- Safety Valves: Boilers are equipped with safety valves to release excess pressure and prevent explosions.

- Pressure Relief Systems: Boilers have pressure relief systems to protect against overpressure conditions.

- Emergency Procedures: Clearly defined emergency procedures should be in place to respond to boiler malfunctions or accidents.

Conclusion

Steam boilers are essential pieces of industrial equipment, providing a reliable and efficient source of steam for a wide range of applications. Their versatility, efficiency, and controllability make them invaluable in various industries. However, ensuring safe operation and adopting appropriate safety measures are crucial to prevent accidents and maintain optimal boiler performance.