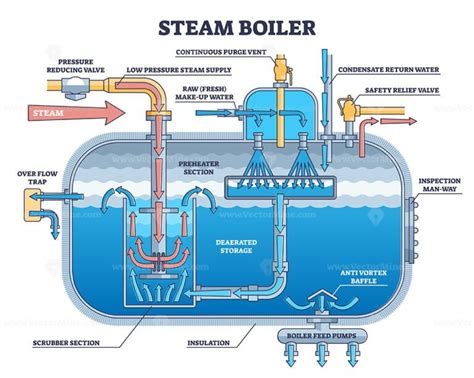

A steam boiler is a device that generates steam for industrial and commercial processes. It operates on the principle of heat transfer, converting water into steam by heating it at a specific pressure.

How Does a Steam Boiler Work?

- Water Input: Feedwater enters the boiler and flows through a series of tubes or pipes, known as the water tubes or water drum.

- Heat Addition: A heating source, such as coal, gas, or oil, heats the water tubes, transferring heat to the water inside.

- Steam Generation: As the water absorbs heat, it transforms into steam, which rises to the top of the boiler.

- Steam Separation: The steam is separated from the water in a steam drum or separator, ensuring that dry steam is produced.

- Steam Output: The dry steam exits the boiler through an outlet pipe, ready for use in various applications.

Key Components of a Steam Boiler

- Fuel source: Provides heat for steam generation.

- Water tubes or drum: Contains the water to be converted into steam.

- Heat exchanger: Transfers heat from the fuel source to the water.

- Steam drum or separator: Separates steam from water.

- Burner: Controls the combustion of fuel.

- Safety valves: Prevent excessive pressure buildup.

Types of Steam Boilers

Steam boilers come in various types, including:

- Fire-tube boilers: Hot gases flow through tubes submerged in water.

- Water-tube boilers: Water flows through tubes heated by external heat sources.

- Electric boilers: Electricity heats the water.

Applications of Steam Boilers

Steam boilers are widely used in various industries, including:

- Power generation

- Chemical processing

- Food and beverage production

- Textiles and paper manufacturing

- Healthcare and laundry facilities

Benefits of Steam Boilers

- High thermal efficiency

- Reliable and durable

- Versatile fuel options

- Low maintenance costs